Karting is gaining more and more popularity, both as entertainment and as a sport. More and more people are wondering about karting: what it is, how it appeared, and how to ride fast.

To give karting the best acceleration, you need to choose a mechanism. There are two options – a kart torque converter and a centrifugal clutch. The torque converter acts as a hydraulic clutch between the engine and the automatic transmission, and the clutch provides maximum acceleration.

So, which one is more suitable for your karting? To better understand which mechanism is right for you, below is a detailed comparison of the torque converter and kart clutch.

What is a torque converter in karting?

The torque converter is one of the options for the power transfer mechanism for typical karts. With a torque converter, you will get low torque, so you can easily control its transmission depending on the unevenness of the ground.

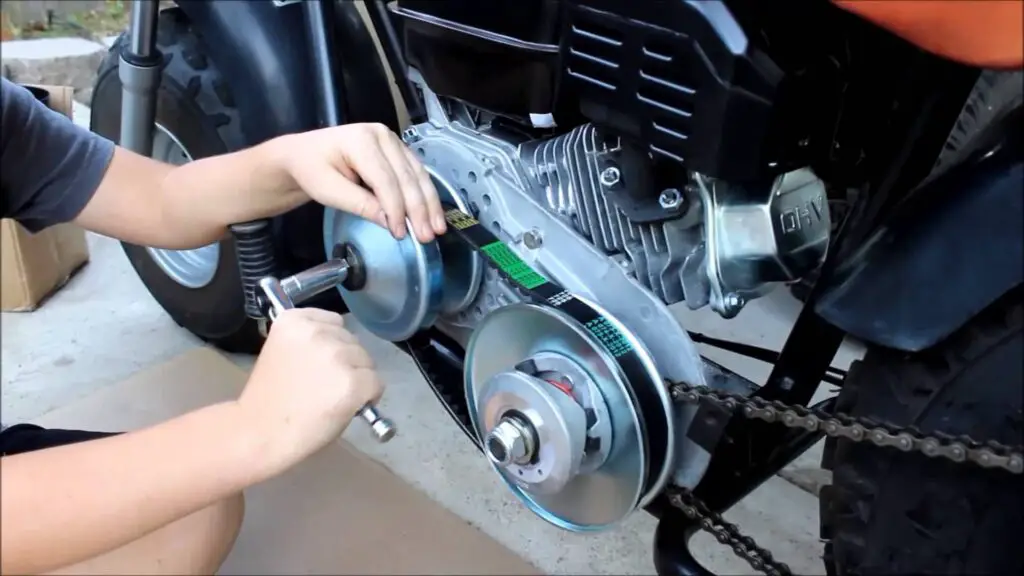

Torque converters consist of two pulleys, one is the driving pulley and the other is the driven pulley. The driver pulley is smaller and connected to the engine crankshaft. The driver pulley is larger and connected to the rear axle. Two pulleys are connected by a belt through which mechanical power is transmitted.

The go-kart torque converter mechanism is designed to increase efficiency by up to 80%. Plus, they allow for low torque and give you unlimited shifting options. In addition, gear variations are fully automatic, and you don’t have to manually adjust them.

Torque converter features:

- It has two pulleys: driving and driver pulley

- The torque converter allows you to change the gear ratio

- It can remain disabled while the engine is idling

- It turns on only when the engine reaches more than 1500 RPM

- Retains 80% efficiency

- It provides low torque

How does a go-kart torque converter work?

The go-kart torque converter works on the principle of continuous variable transmission (CVT). This means one pulley acts as a clutch while the other is driven. The clutch or driver pulley is powered by the centrifugal force of the engine.

The driver pulley senses the torque and allows you to change the variable gear ratio, making it adaptable to various unevenness. In addition, both pulleys are made up of movable pulleys providing different power ranges.

The crankshaft of the engine drives the clutch pulley under centrifugal force.

When the engine reaches higher revolutions per minute (RPM), the movable pulley helps the clutch pulley move inward. The belt connecting both pulleys will proceed with a larger diameter in the clutch pulley. The belt diameter on both pulleys varies with torque.

When the engine is idling, the torque converter stays at rest.

Thus, even if you leave the engine idling, the go-kart torque converter will be disabled until it gets a certain RPM. This number of revolutions for most torque converters is 1500. This is how the engine’s mechanical power is transferred to the rear axle.

What is a go-kart clutch?

The centrifugal clutch is another mechanism for transferring power from the engine to the rear axle. This is the best opportunity for kart racing as it provides maximum speed. This mechanism does not let gear changes and operates with a fixed gear ratio. This means that for the entire engine speed range, the clutch will have a one-gear ratio.

Unlike the system with two go-kart torque converter pulleys, there is only one disc. It contains all the different clutch components that help in power transmission. These are the outer casing of the drum, friction lining, retaining spring, drive sprocket, and weights.

The clutch connects the rear axle with a roller chain and sprocket.

In terms of efficiency, clutches function better than torque converters because they can be as efficient as 100%. In addition, the clutches work with high torque, which allows them to work faster. In addition, various multi-disc kart clutches allow you to ride even in conditions that require a larger gear ratio.

Features of a centrifugal clutch

- It consists of only one disc, which has a drive sprocket, an outer drum, a retaining spring, and friction material

- Clutches use a chain and sprocket to connect to the rear axle

- It has a fixed gear ratio that helps maintain top speed

- Stays on even when the engine is idling

- It turns on completely when the engine speed exceeds 1800 RPM

- Provides high torque

- It maintains an efficiency of over 100%

How does a centrifugal clutch work?

The clutch works like the driver pulley of the go-kart torque converter. It has only one disk, on which all its components are present. It is located on the crankshaft of the engine and moves under the influence of centrifugal force from the engine. This force is transmitted to the clutch through its weights, also known as clutch shoes.

It operates a retaining spring to keep all of its internal parts from contacting the outer drum. That’s why the clutch starts to engage only after the engine reaches 1400-1600 RPM. It becomes fully operational at about 1800 RPM, until then, it continues to slip.

Once the clutch pads begin to rotate, they will come into contact with the outer drum drive sprocket, which will then transfer power to the rear axle.

Because the clutch moves at the same speed as the engine, there is no energy loss. This makes the clutch much faster than torque converters.

The main problem with clutches is slippage. To control slippage, it is necessary: firstly, to use it on flat tracks at high speed. Ideally, it should run at over 2000 RPM. Secondly, never press the brake at the same time as the go-kart clutch, this will increase the load on the engine. Lastly, always use a quality system lube to keep it intact.

Pros and cons of torque converters and clutches

Pros of the torque converters

- Variable gear ratio for better kart movement

- Suitable for off-road go-kart on the streets or other places

- It needs a lower level of maintenance

- Easy to operate as they have automatic gear shifting

- Allows for a variety of riding styles

- Saves the go-kart’s engine from wear as it starts at 1500 RPM

Cons of the torque converters

- It has less efficiency

- Slightly more expensive than centrifugal clutches

- The belt can quickly fail due to heat

Pros of centrifugal clutches

- Offers a fixed gear ratio that provides a greater top speed

- Best suited for kart racing on flat tracks

- It has a much higher efficiency than torque converters

- Easy to install

- Allows for better power transfer

- The roller chain mechanism does not wear out quickly

Cons of centrifugal clutches

- Requires a higher level of maintenance

- Not suitable for different riding styles

- There is a risk of slipping at lower speeds

- Overheats easily

4 steps torque converters adjustment

- Remove the face chamber from the drive pulley

The first step is to remove the nut and washer from the fixed cam on the drive pulley. Under it is a retaining ring, which must be removed with long-nosed pliers.

Be sure to hold on to the drive pulley, as it is spring-loaded and may come off the plate. The surface of the cam (the plate that holds the spring) can be damaged if it falls to the ground.

- Adjust the position of the spring

With the cam divided from the torque converter, adjust the spring. You can switch springs for different types, but the main adjustment you will likely make is the position of the spring.

The spring is in the middle of the three fixed cam positions. To make the necessary adjustment, it is necessary to move the spring to the first or third position. Torque converters are marked on each port. The higher the number (from left to right), the greater the torque of the kart.

- Replace face cam

You can replace the face cam by reordering or taking it apart, but it’s a little more difficult because you’ll need to preload the torque converter. The spring inside the torque converter must be coiled and tensioned.

The first step is to place the spring in the desired position on both the fixed cam and the surface of the cam. The flat sides must then be aligned on both the fixed cam and the cam surface.

- Torque converter preload

The next step is to preload the torque converter. Next, you need to press the front side of the cam to the fixed cam and turn it counterclockwise until it stops.

From there, you have to maintain pressure on the plate as you push the retaining ring back into place. All that’s left to do is screw the nut back into place.

Common karting torque converter problems

- Torque converter belt slip

The belt can slip off the pulleys from time to time. Common causes are incorrect belt size, misaligned pulleys, or worn pulleys.

- Kart jerks when accelerating

Your kart should have smooth acceleration even at the highest torque settings. The problem is using the wrong torque converter belt or the drive needs cleaning and lubrication.

- The torque converter does not turn off

Releasing the accelerator pedal should return the pulleys to neutral. If not, or if the kart is slow to idle, the issue is with the torque converter.

A quick cleaning and inspection of it can solve this problem.

- The kart is idling

If you notice your kart juddering at idle, a torque converter or engine tuning is required. Your kart should idle without the rear axle spinning. The issue is that the clutch engages minimally when it should be a little higher.

FAQs

Is a torque converter better on a go-kart?

Go-kart torque converters are great for low torque applications as they can adjust the gear ratio based on engine RPM. This makes it ideal for heavier or off-road karts.

Is a torque converter better than a centrifugal clutch?

The answer depends on driving habits. Because go-kart torque converters are easier to handle in the low torque range, they are most commonly used on off-road karts. They work better at low speeds and are ideal for frequent stops. Clutches, on the other hand, are faster and work better at high speeds. They are designed for continuous use, making them ideal for kart racing.

So, when comparing a kart torque converter to a clutch, you need to make your choice based on what you intend to use it for.

How does the torque converter system work?

The go-kart torque converter housing is connected to a flywheel rotating at the same speed as the crankshaft inside the turbine housing. An impeller or centrifugal pump effectively forces the transmission fluid into the fins of the turbine, which in turn rotates or transmits torque to the transmission.

How do you adjust the torque converter on a go-kart?

Go-kart torque converter adjustment in 4 easy steps:

- Remove the nut, circlip, cam, and spring. To adjust the go-kart torque converter, you must access the spring.

- Adjust the spring.

- Assemble the nut, circlip, cam, and spring.

- Pre-tension the spring and assemble the retaining ring and nut.

Is a go-kart torque converter the same as a clutch?

Like a centrifugal clutch, the go-kart torque converter also sends mechanical power to the rear axle, but still allows easy gear changes. It works with two pulleys which automatically assist in the variable transmission of mechanical power. Also, it stays disabled at lower RPMs.

Conclusion

Go-kart torque converters and clutches are kart transmissions with different strengths and weaknesses. They perform the same function but work in completely different ways, and the best transmission for your kart depends on your driving habits and the purpose of the go-kart.

Racing karts are most often equipped with a clutch that performs better at high RPM and achieves maximum speed. On the other hand, torque converters are more commonly used in off-road karts, which are mostly used for heavier loads and lower speed ranges.