When your clutch is experiencing problems, look for signs such as poor acceleration, grinding noises during, or a slow take-off. When facing problems related to clutch engagement, try to examine the engine and clutch. Common issues causing early engagement include high engine idle speed or loose tension springs. Adjusting the engine idle speed or ensuring proper tension can rectify these concerns.

There is a lot more to know if you are interested in knowing Centrifugal Clutch issues and solutions. Go through this whole article to understand how to tell if centrifugal clutch is bad or not.

Key Takeaways

- Look out for signs like lack of acceleration, grinding noises, and slow take-offs, which could indicate a malfunctioning clutch that needs attention.

- If your clutch engages early or experiences issues, check for problems like high engine idle speed or loose tension springs.

- Prevent overheating by addressing factors like inadequate lubrication, tire size for gear ratio, and low-speed operation to ensure the clutch’s durability.

- In cases of a clutch stuck to the crankshaft due to heat or wear, you can replace affected parts for improved performance.

How Can You Understand That Your Centrifugal Clutch Is Bad?

To understand if your centrifugal clutch is bad, you can watch out for the following signs:

Go-Kart Isn’t Accelerating:

When your go-kart lacks proper acceleration, it might suggest a problematic clutch. A worn-out clutch might fail to engage effectively. It results in reduced power and sluggish acceleration. This can be due to worn-down clutch shoes.

Also ensuring proper and complete engagement of a go-kart’s clutch is essential for optimal performance. The clutch generally achieves full engagement at around 1,800 rpm. It signifies that centrifugal force has effectively brought the flyweights and friction material into contact with the clutch drum.

Grinding Noise During Acceleration:

Another red flag for a faulty clutch is the grinding noise happening when you accelerate. This noise could stem from deteriorating clutch plates. The grinding noise may also result from the clutch drum rubbing against the clutch shoes. It can be caused by not enough lubrication in the clutch.

Slow Take-Off:

If your go-kart uses a centrifugal clutch, it is possible to have issues like slow or boggy take-off. This issue often arises from worn-down clutch shoes. Additionally, over time, the clutch shoes might become glazed, which leads to slipping and improper engagement.

How Can You Fix If Your Centrifugal Clutch Is Bad?

Problem 1:Centrifugal Clutch Won’t Engage

A go-kart’s clutch achieves full engagement at approximately 1,800 rpm. At this point, centrifugal force brings the flyweights and friction material into contact with the clutch drum.

That’s why you need to ensure proper and complete engagement for optimal clutch performance.

Failure to engage correctly can result in delayed or jerky starts when pressing the accelerator.

Potential problems that can cause this engaging issue are:

- Worn-out friction material

- Incorrect lubrication

- Excessively tight tension springs

Manufacturers typically set 1,800 rpm as the engagement point for clutches. Achieving this threshold ensures proper contact between the clutch drum and frictional material through centrifugal force.

That’s why you need full clutch engagement for trouble-free operation. If engagement is not smooth, you might experience jerks while pressing the pedal.

Solution:

You can troubleshoot the Centrifugal Clutch Engaging Issues by following these guidelines

Worn Out Friction Material:

One prevalent issue with go-kart clutches is worn-out friction material. Regular use can lead to wear and tear, affecting the engagement of the clutch. In such cases, replacing either the flyweights or the entire clutch is necessary. Maintenance of these components is crucial to ensure proper clutch functionality over time.

| Product name | Feature |

| Go Kart Clutch 3/4″ Bore 12T | It is Made of good quality iron material. Also, durable and sturdy. |

Incorrect Lubrication:

Incorrect lubrication is another problem that can arise. Lubricating the wrong areas within the clutch can have effects on its performance. For example, it can face a reduction in the necessary friction slipping and poor engagement

To rectify this, it might be required to disassemble the entire centrifugal clutch and remove the excess lubricant. It’s essential to avoid lubricating the friction material, flyweights, or drum to prevent such issues.

Tension Springs Too Tight:

Tension springs that are overly tight can lead to difficulties in clutch engagement. If you encounter this issue, a straightforward solution is to replace the tension springs with standard ones. A clutch’s smooth operation depends on proper tension.

In summary, addressing these common problems with go-kart clutches involves careful consideration and maintenance. Regular checking will help keep your go-kart running optimally.

Problem 2: Excessive Clutch Overheating

When your go-kart’s clutch begins to slip, you might detect a burning smell coming from the burning lining. This slipping action leads to overheating, which can result in detrimental consequences.

You can have an overheating clutch because of various factors. Such as

- Inadequate lubrication.

- The rear tire is too large for the gear ratio

- Operating a go-kart at a continuous low-speed overtime

Areas such as the hub and regions beneath the brass bushing require sufficient lubrication. If these components lack lubrication, excessive heat will be generated over time, leading to the deterioration of the go-kart clutch.

Solution:

You can perform the following suggestion to solve the overheating problem:

Addressing Lubrication Issues:

The most prevalent cause of overheating is the lack of proper lubrication. When the clutch lacks adequate lubrication, there won’t be any fluid to mitigate friction and dissipate heat. It’s crucial to ensure that the hub areas beneath the brass bushing receive proper lubrication.

Exercise caution during lubrication to prevent the application of lubricant to clutch internal components.

Dealing with Oversized Rear Tires for Gear Ratio:

Gear-to-tire ratio for a 13′ tire is 1:6 (Gear ratio: Teeth in axle sprocket ratio). Any tire size exceeding this gear ratio can cause significant heating. If you intend to increase your go-kart’s tire size, it’s necessary to make a corresponding gear ratio reduction to maintain compatibility.

Overheating Due to Prolonged Low-Speed Operation:

Although it may seem surprising, driving a go-kart at consistently low speeds for an extended period can trigger clutch overheating. This occurs because the clutch remains fully engaged for a prolonged duration.

To counter this, it’s important to lubricate your go-kart clutch with a suitable lubricant or oil. During the lubrication process, ensure that the application is limited to the area around the brass bushing.

Maintain caution to avoid lubricating the ventilation holes, as this could inadvertently lead to lubrication of the internal friction materials. However, if you are interested in Manco go-kart then you can explore Manco go-kart models and their identification.

Problem 3: The Clutch Is Stuck to the Crankshaft

A key point of origin for this problem is when the go-kart clutch is removed from the crankshaft. In cases of prolonged overheating or extensive wear, a go-kart clutch can face the issue of its internal components becoming stuck together.

Over time, consistent overheating or insufficient lubrication can facilitate the transfer of heat from the external components to the internal ones.

This heat transfer causes the internal temperature to rise significantly. It generally results in the melting and subsequent fusion of the metal components.

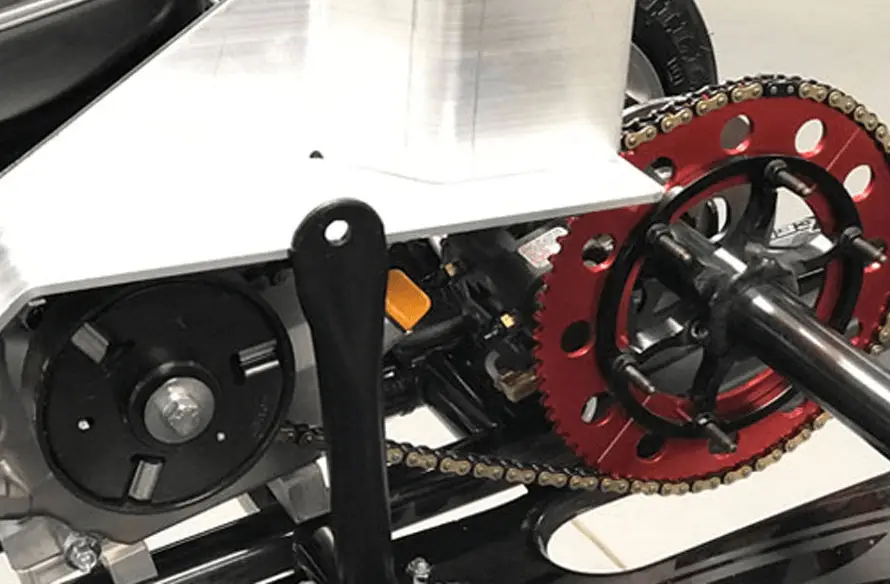

Commonly affected parts include friction materials (flyweight/shoe), clutch drum, and even tension springs or pivots.

Solution:

You can follow these steps when you are facing issues in your go-kart like the clutch Is stuck to the crankshaft:

- Begin by spraying oil on the frozen parts of the clutch to help loosen them up. Allow the oil to soak in, as this can facilitate the removal process.

- If the clutch still doesn’t come out after applying oil, it’s advisable to use a 3-jaw gear puller. This tool can exert controlled force to gradually pull the clutch away from the crankshaft.

- While using the gear puller, exercise caution to avoid damaging the clutch. Sometimes, the clutch may be tightly stuck to the crankshaft, and excessive force can result in severe clutch damage.

- To make future disassembly easier, consider applying some anti-seize onto the crankshaft. This can prevent the clutch from sticking again and facilitate smoother maintenance in the future.

Problem 4: Clutch Engages Early

During your go-karting experiences, you might have observed the phenomenon of the go-kart accelerating as soon as the engine starts. This occurrence indicates an early engagement of the clutch, which can be attributed to various factors.

To address this issue, a careful examination of both the engine and the clutch is necessary.

Potential causes of a go-kart engaging the clutch too early include:

- Engine Idle Speed Set Too High

- Clutch Components Being Stuck

- Tension Springs Being Too Loose

Among these issues, a common problem leading to early clutch engagement is an excessively high engine idle speed. It’s important to note that this clutch-related concern is linked to the engine’s idle speed rather than the clutch itself.

Solution:

To address this issue, a careful examination of both the engine and the clutch is necessary. So, you can follow these steps:

Engine Idle Speed Set Too High:

The engine idle speed configuration can be adjusted by manipulating idle engine screws. This approach is applicable when the engine’s idle speed is set too high. Also, consult your go-kart’s manual for instructions on how to reduce the idle speed appropriately.

Clutch Components Are Stuck:

An immediate engagement of the clutch upon engine startup can be due to flyweights being stuck to the drum. Depending on the extent of the issue, you may need to replace either the flyweight or the entire clutch assembly.

When Tension Springs Are Too Loose:

Over time, tension springs can lose their tension, which results in premature clutch engagement. When you notice that your clutch is engaging too early, check the tension springs for wear or looseness.

If necessary, replace the worn or loose tension springs and reinstall the go-kart clutch.

By addressing these factors, you can rectify the issue of early clutch engagement and ensure smoother go-kart operation.

What Are the Centrifugal Clutch Maintenance Tips?

Maintaining your centrifugal clutch is crucial to ensure optimal performance and longevity. Here are some valuable maintenance tips to follow:

Try to Follow the Maintenance Schedule:

To avoid potential issues, establish a consistent maintenance schedule. Proper upkeep can extend the service life of your high-quality clutch.

Clean and Lubricate Properly:

Accumulated dirt and debris can hinder clutch engagement. Regularly clean components using a soft-bristled brush. Apply a light layer of lubricant to the clutch bushing and pivot points to prevent sticking. However, it is also necessary to understand whether you can spray wd40 in a spark plug hole or not.

Oil the Bushing:

Regularly oil the sprocket’s bushing, particularly after every two hours of driving, to prevent excessive wear and heat buildup. However, avoid oiling the holes on the drum section, as this can lead to excess slippage and heat generation.

Avoid Overloading:

Stay within the designated weight limit of your centrifugal clutch. Overloading can accelerate clutch wear and compromise its lifespan. Generally, ensure that the combined weight of the kart, driver, and passengers (if applicable) does not surpass 400 pounds.

Regular Inspections:

Conduct routine inspections to identify signs of wear or damage. Heat damage can be evident by the change in color of the metal inside the clutch drum. If any wear or damage is detected, consider replacing the clutch.

By maintaining these guidelines, you can promote smooth operation and longevity of your centrifugal clutch. Always prioritize safety measures and consult the manufacturer’s instructions when performing maintenance on your go-kart’s centrifugal clutch.

Frequently Asked Questions (FAQs):

What Is Better Than a Centrifugal Clutch?

A torque converter is better than a centrifugal clutch if you want to work with heavy loads. Torque converters are more suitable for power transmission applications involving heavy loads. However, centrifugal clutches are better suited for power transmission applications at high speeds.

Do Centrifugal Clutches Wear Out?

Yes, centrifugal clutches can wear out. These clutches are engineered to handle a specific weight capacity. If this weight limit is surpassed, the clutch’s lifespan will be reduced. To maintain longevity, a guideline is to ensure that the combined weight of the kart, does not surpass 400 pounds.

What Is the Most Aggressive Clutch?

The most aggressive clutch material is sintered clutches. They feature an abrupt on/off engagement and are commonly employed in drag cars and competitive settings. These clutches often necessitate specialized flywheels and are available in “paddle” style discs.

Conclusion

Now you have an idea of how to tell if centrifugal clutch is bad.

When a centrifugal clutch is exhibiting signs of malfunction, it’s important to address the issue to ensure the longevity of your Go-Kart. If you notice symptoms like delayed acceleration, grinding noises, or overheating, it’s time to take action.